SINCE 1995

SOLUTIONS

RELIABLE SYSTEMS & SOLUTIONS

At BLACKSMITHS, we are committed to engineering and delivering high-quality recycling systems. Our strength lies in providing complex process solutions that are both simple in operation and highly effective in performance. As a leader in the engineering, design, construction, manufacturing, installation, and servicing of advanced process systems, our focus is rooted in the EEE principles: Economic, Ecologic, and Ergonomic efficiency.

TRANSFORMING BY-PRODUCTS INTO VALUABLE END-PRODUCTS

BLACKSMITHS specializes in the development and implementation of high-performance recycling processes. From individual components to fully integrated turnkey systems, we provide customized solutions designed to extract maximum value from by-product materials. Our goal is to minimize waste and optimize resource recovery by converting residual materials into valuable end-products.

QUALITY DRIVEN BY EXPERIENCE

With decades of industry expertise, BLACKSMITHS is uniquely positioned to optimize your processes for superior product quality and improved profitability. We deliver cost-effective solutions that ensure optimal material handling while meeting the highest hygiene standards. Our portfolio includes a wide range of standalone equipment and complete processing lines—available in both standard configurations and tailored designs. As your trusted partner for turnkey projects, BLACKSMITHS Rendering delivers performance, reliability, and innovation in every solution.

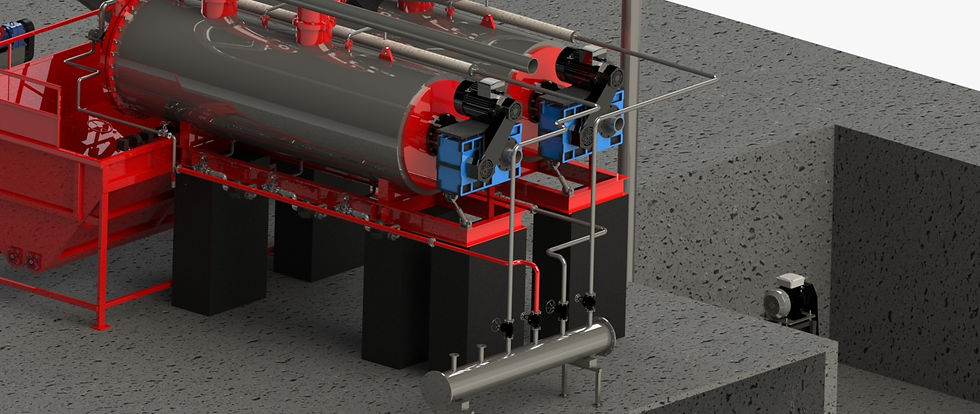

BATCH COOKER

Batch cookers are used for the batch cooking process as described in the processing section. The purpose of the batch cooker in the rendering process is to condition, sterilize, hydrolyze and dry the product. If your company renders white meat (poultry), red meat, feathers, blood or a mixture of by-products the batch cooker is the perfect solution for you.

Blacksmiths Model Batch Cookers are the long-standing industry standard in rendering batch cookers. Constructed of heavy duty, pressure vessel rated steel with dished heads (ends) which allows for the units to be used for internal pressure applications such as hair or feather hydrolyzing. The units are available with a multitude of configurations and options to fit every plant and every budget.

-

Insulation of body and/or heads for improved thermal efficiency

-

Deep stuffing boxes or mechanical seals.

-

Manual ,Motorized or hydraulic swing gate or knife gate valve on the discharge and inlet

-

Multiple loading dome configurations

-

MOC- Mild Steel , Carbon Steel

-

Loading Capacity- 1-8 Tonne (Raw Material)

-

Special Shaft Configuration.

-

Standard IBR Valves

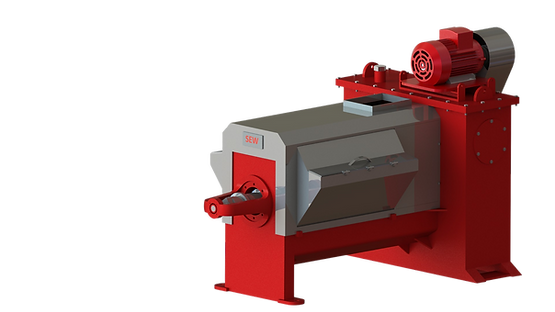

FAT SCREW PRESS

Years of experience have contributed to the development of superior and hard-wearing pressing machinery by Haarslev which enhances the value of the end products: feather presses, two ranges of expeller presses, twin-screw press range with both conical or bi-conical options for fish and wet rendering, exceed all expectations.

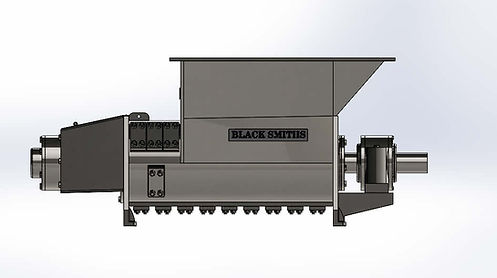

PRE-BRAKER OR CRUSHER

Low speed crushers, fast running crushers, twin shaft crushers, frozen block crushers, fine crushers are just some of the wide range of possibilities available from. Blacksmiths all sharing common characteristics of high capacities, proven durability and ease of maintenance.

BATCH COOKER

Batch cookers are used for the batch cooking process as described in the processing section. The purpose of the batch cooker in the rendering process is to condition, sterilize, hydrolyze and dry the product. If your company renders white meat (poultry), red meat, feathers, blood or a mixture of by-products the batch cooker is the perfect solution for you.

Blacksmiths Model Batch Cookers are the long-standing industry standard in rendering batch cookers. Constructed of heavy duty, pressure vessel rated steel with dished heads (ends) which allows for the units to be used for internal pressure applications such as hair or feather hydrolyzing. The units are available with a multitude of configurations and options to fit every plant and every budget.

-

Insulation of body and/or heads for improved thermal efficiency

-

Deep stuffing boxes or mechanical seals.

-

Manual ,Motorized or hydraulic swing gate or knife gate valve on the discharge and inlet

-

Multiple loading dome configurations

-

MOC- Mild Steel , Carbon Steel

-

Loading Capacity- 1-8 Tonne (Raw Material)

-

Special Shaft Configuration.

-

Standard IBR Valves